Features

Features

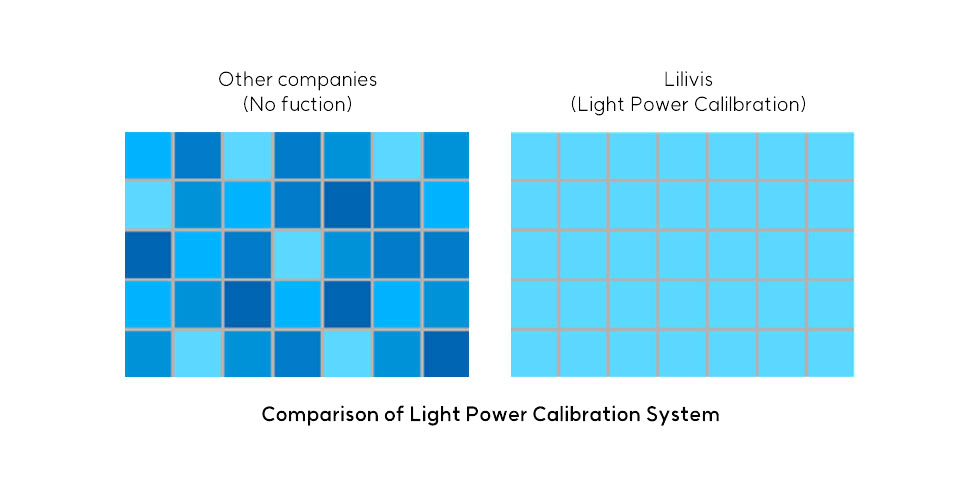

LSA-Light Power Calibration System

Improved printing precision by automatically measuring and correcting the amount of light to

maintain the same amount of light (95% overall light uniformity) and light uniformity.

Securing uniformity of light quantity through photodetection.

maintain the same amount of light (95% overall light uniformity) and light uniformity.

Securing uniformity of light quantity through photodetection.

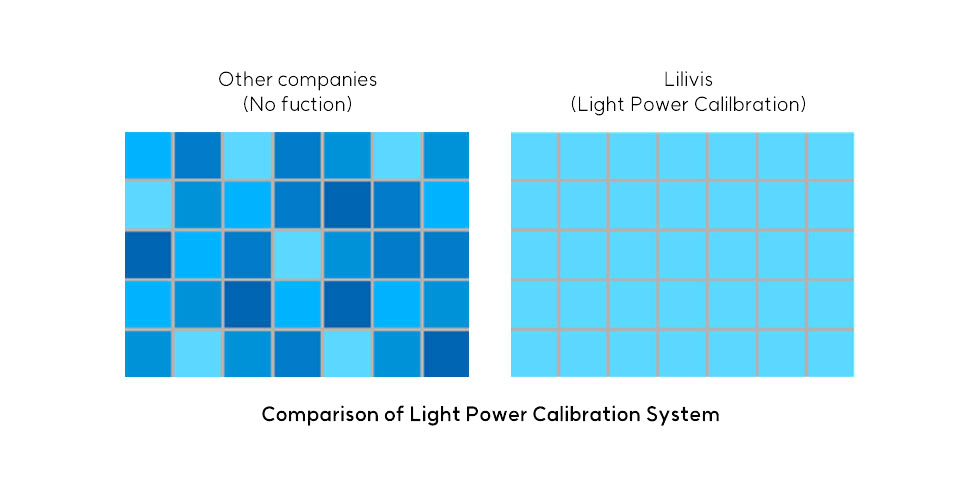

LSA-Light Power Calibration System

Improved printing precision by automatically measuring and correcting the amount of light to

maintain the same amount of light (95% overall light uniformity) and light uniformity.

Securing uniformity of light quantity through photodetection.

maintain the same amount of light (95% overall light uniformity) and light uniformity.

Securing uniformity of light quantity through photodetection.

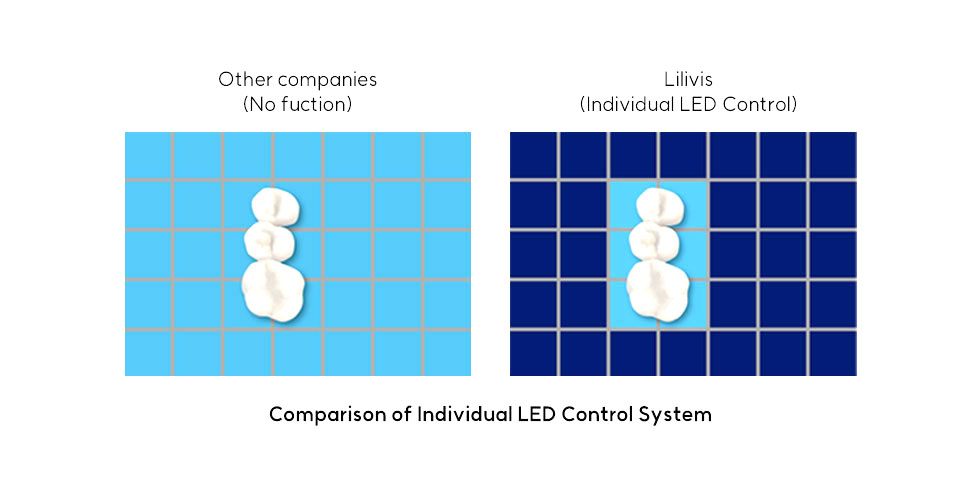

LSA-Individual LED Control System

By counting the LED usage time and automatically selecting and using only the LEDs needed for output,

it reduces repetitive fatigue and prevents LCD panel damage and enhances equipment durability.

it reduces repetitive fatigue and prevents LCD panel damage and enhances equipment durability.

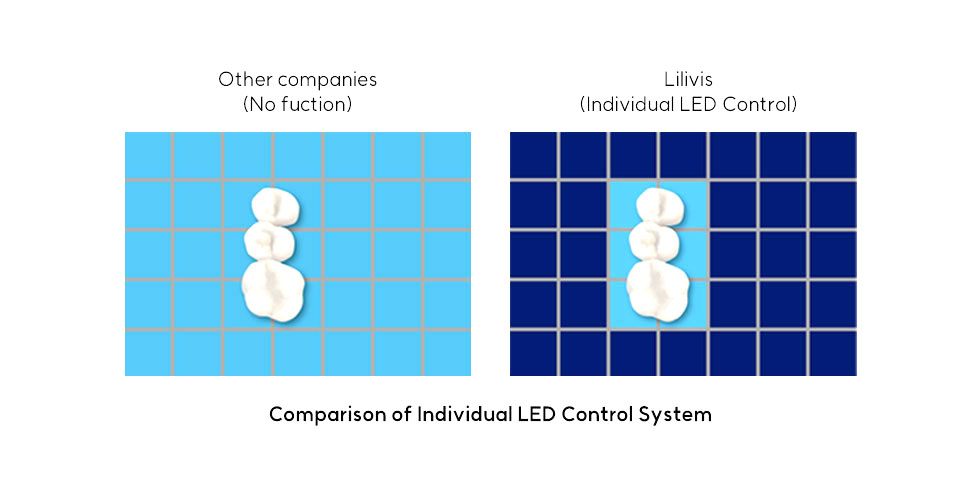

LSA-Individual LED Control System

By counting the LED usage time and automatically selecting and using only the LEDs needed for output,

it reduces repetitive fatigue and prevents LCD panel damage and enhances equipment durability.

it reduces repetitive fatigue and prevents LCD panel damage and enhances equipment durability.

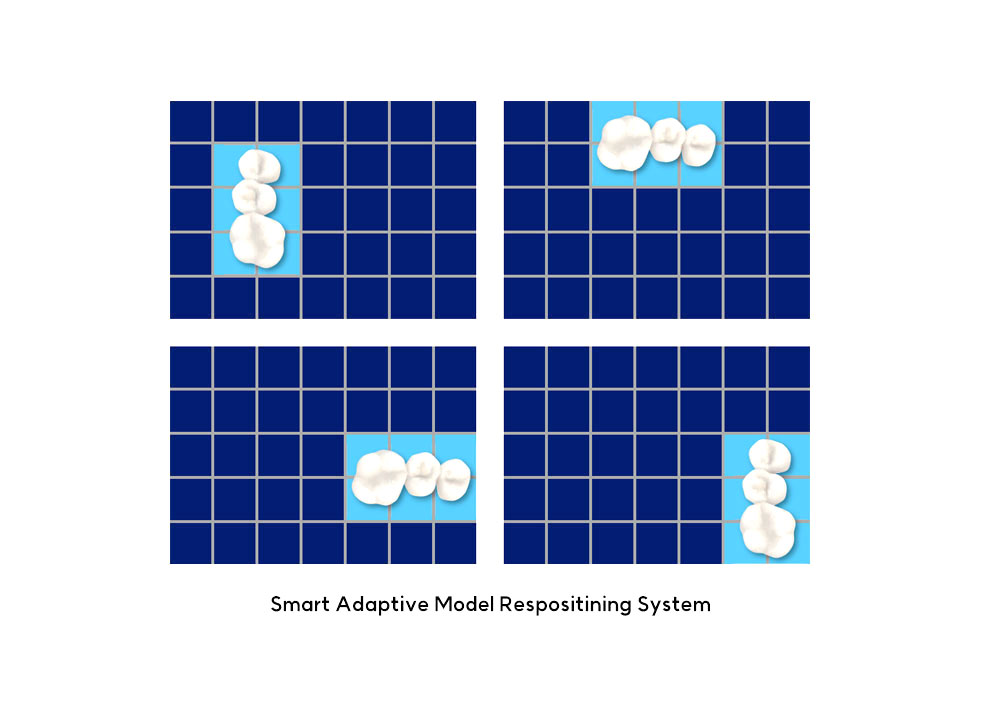

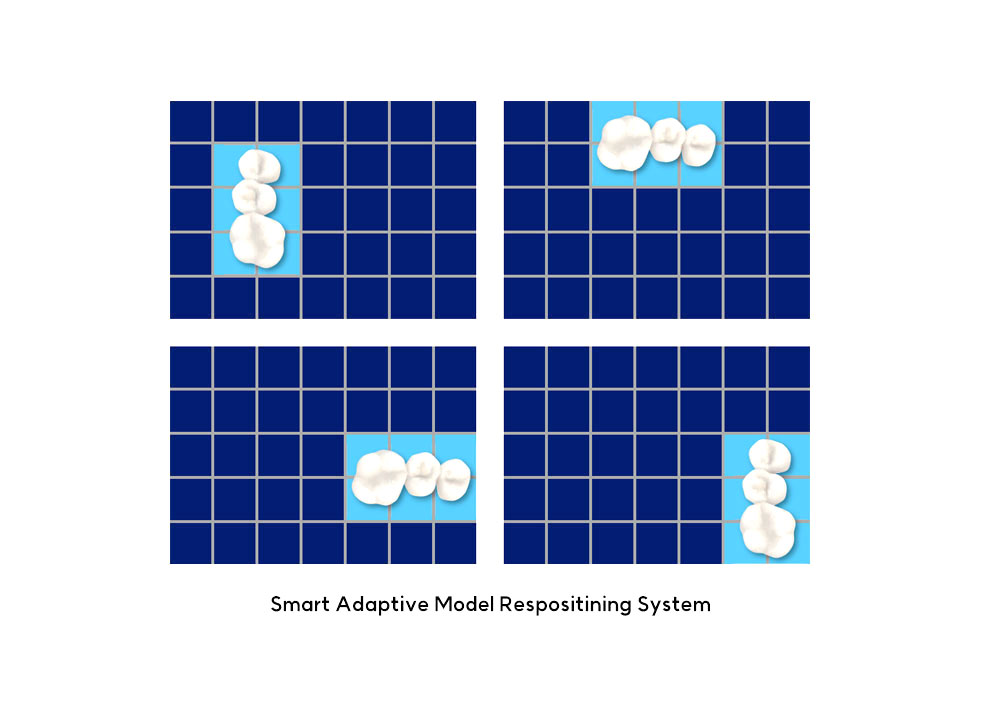

LSA-Model Repositioning System

Through the LSAS-Mode Repositioning System, the optimal output position is automatically searched for and then

printed to reduce the fatigue accumulation of LED, Film and LCD panels and maintain the best quality.

printed to reduce the fatigue accumulation of LED, Film and LCD panels and maintain the best quality.

LSA-Model Repositioning System

Through the LSAS-Mode Repositioning System, the optimal output position is automatically searched for and then

printed to reduce the fatigue accumulation of LED, Film and LCD panels and maintain the best quality.

printed to reduce the fatigue accumulation of LED, Film and LCD panels and maintain the best quality.

Specifications

Specifications

Lilivis Print

| Printing Type | Adaptive MSLA |

|---|---|

| Build Size | 120 x 75 x 120mm |

| Pixel Size(X/Y) | 50 um |

| Light Source | 405 um |

| Z Resolution | 10 um ~ 200 um |

| 10 um ~ 200 um | Open Material |

| Build Plate Type | Leveling Free |

| Input Power | 100-120 Vac / 220-240 Vac |

| Machine Size | 300 x 300 x 380 mm |

| Weight(Net) | 16 Kg |

Lilivis Cure

| Chamber Size | Ø150 x 100 mm |

|---|---|

| LED Position | Top 20 ea, Side 10 ea |

| Light Source | 395 nm UV LED |

| Input Power | 100-120 Vac / 220-240 Vac |

| LED Output Power | 280W |

| Machine Size | 280 x 280 x 300 mm |

| Weight(Net) | 8.5 Kg |

* Specifications and designs are subject to change without notice

Lilivis Print

| Printing Type | Adaptive MSLA |

|---|---|

| Build Size | 120 x 75 x 120mm |

| Pixel Size(X/Y) | 50 um |

| Light Source | 405 um |

| Z Resolution | 10 um ~ 200 um |

| 10 um ~ 200 um | Open Material |

| Build Plate Type | Leveling Free |

| Input Power | 100-120 Vac / 220-240 Vac |

| Machine Size | 300 x 300 x 380 mm |

| Weight(Net) | 16 Kg |

Lilivis Cure

| Chamber Size | Ø150 x 100 mm |

|---|---|

| LED Position | Top 20 ea, Side 10 ea |

| Light Source | 395 nm UV LED |

| Input Power | 100-120 Vac / 220-240 Vac |

| LED Output Power | 280W |

| Machine Size | 280 x 280 x 300 mm |

| Weight(Net) | 8.5 Kg |

* Specifications and designs are subject to change without notice

Video

Video